This article is from the third book in a multi-volume series entitled "Building America." First published in 1936, my sister found this updated version from 1942 being given away in her university library. The subject matter is fantastic, the covers beautiful, and the colors match mine and Jacob's home decor, so she snatched them and gave them to me!

The book series covers many aspects of American life such as farming, heavy industry, war and peace, education, culture, healthcare, and even clothing. It's a really interesting look at America and it's history from a 1942 perspective.

I found this article on the chemical science behind the "new" fabrics of the day especially fascinating. Buttons made of milk, mercerization, and the connection between viscose and rayon... just a few of the interesting tidbits explored in the article! It was a bit tricky to try to scan a hardback book, so I've typed out the complete article for your reading pleasure below:

Modern Clothing Depends on Chemical Science

Chemical products are important in the process of making the clothes we wear. Before wool and silk, cotton and linen, can be used by the spinner and the weaver they must go through many chemical processes. And within the past thirty years, the chemist has perfected a new set of textile fibres--the rayons.

The chemist develops ways to free fibres such as wool and silk from foreign matter and impurities of many kinds before they go to the spinner. These fibres are washed with specially made soap-like compounds until they are clean and pure.

|

| Left photo: Winding rayon threads on spools, after which these threads are woven into cloth or clothing. Rayon, a chemical product, is made in somewhat the same way as Cellophane. Right photo: Testing a sample of dye to be used on a print fabric. This modern chemist has produced hundreds of shades which our forefathers never saw in garments. |

Fibres and fabrics are bleached chemically for use as "white goods" or to prepare them for the dyeing process. Many years ago bleaching was done by soaking fibre or cloth in vinegar or buttermilk, or by spreading out linen and cotton in the sun. But as the production of these fires increased with the use of power looms, a more practical way was needed. It was then that chemical bleaches were first used. At first, bleaching powders were made by combining chlorine with lime and water. Although for many years the textile industry used this method for whitening materials, it was not quite satisfactory since this bleaching process sometimes weakened the fibers and made them unfit for use. Today other chemical compounds are used which make the chlorine harmless after it has done its bleaching work.

In the dyeing of cloth the chemist performs another valuable service. At first, as explained earlier, the only coloring materials used were those gotten from natural products. Now the chemist makes many thousands of colors from coal-tar. The manufacture of these synthetic dyes is an interesting and complicated chemical procedure.

|

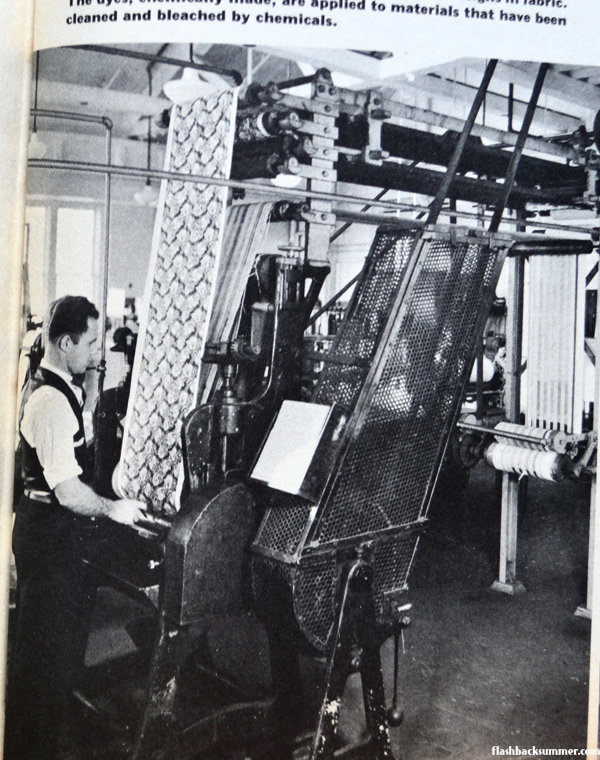

| Trying out dyes on a machine that prints designs in fabric. The dyes, chemically made, are applied to materials that have been cleaned and bleached by chemicals. |

We often see the word "mercerized" used in connection with cotton fabrics. Mercerization is a chemical process which makes cotton resemble more expensive material. This is done by putting woven fabric in a solution of caustic soda. When the soda is rinsed out the fabric has a silkier and more attractive-looking finish.

One of the marvels of modern chemistry as applied to the manufacture of clothing is that of rayon. Rayon is a textile fibre chemically produced from cellulose which is the main element in the cells of all plants and trees. Spruce, the wood used to make Cellophane, is also used in making rayon.

As early as 1664, scientists were seeking a man-made fibre. In 1884, a Frenchman named Count Hilaire de Chardonnet studied the silkworm and the chemical composition of the mulberry leaf on which the silkworm feeds. He found that the silkworm's food was made up mainly of cellulose, and it was possible to "digest" it chemically and then to force the cellulose solution through a tiny hole and solidify it. He called his method the nitro-cellulose process. This man-made fibre was introduced in the United States in 1910 and was sold as "artificial silk," "glos," "synthetic silk," and under many other names. In 1924, manufacturers agreed on the name "rayon" for all man-made fibre based on cellulose. They have been known by the name ever since, although the chemical process used by de Chardonnet is no longer used in the United States.

Today, rayon is made from spruce wood and cotton fibre by dissolving the cellulose in them with chemicals. This forms a thick liquid known as viscose. After a series of chemical baths the viscose is forced through tiny holes from which it drips in filaments as fine as silk fibre. These filaments are then twisted together to make thread or yarn.

|

| In the clothing of this man and woman are chemical products such as rayon in the gown and tie, and a coating for the heels of shoes that prevents "scuffing." |

Rayon has become a very important textile material, and in 1937 one billion yards of rayon material went into dresses, underwear, piece goods and linings.

A large variety of chemical products are used to make leather for our shoes, belts, gloves, purses, wallets, and luggage. Chemistry has also produced many substitutes for leather and tanning.

The very buttons on our clothing are now being made of substitute materials by means of chemical processes. The waste skim-milk of the dairy supplies the chemist with casein from which he makes a plastic material that can be molded into buttons.

Perhaps we most often think of chemistry as applied to clothing when we use a cleaning fluid. The most common chemicals used are benzine, gasoline, and naphtha. These are inflammable, and recently chemists have found safe substitutes for them.

Did you learn anything new from this article? Will it affect how you view or care for your vintage clothing?

I love rayon and this article was so interesting! Did you know that casein is also now made into knitting needles and yarn? I haven't knit with the yarn - yet. It's supposed to be really soft and light.

ReplyDeleteI didn't know that! The yarn sounds like it would be lovely!

DeleteI had no idea how rayon was made! Very informative.

ReplyDeleteGlad to hear it!

DeleteThat is so interesting! I knew a bit about different fabrics, but not specifically how they are made. Thanks for sharing :)

ReplyDeleteThe Artyologist

Isn't it?! I learned a lot, too.

DeleteThat was really interesting. Thanks. I knew some of that but not all.

ReplyDelete